Our Sino-based engineering staff works together to help you prototype, design, test, build, and manufacture your custom display solution to perfectly fit your application and make your product a success. Keep in mind that minimum order quantities (MOQ) and NRE may apply depending on your custom solution request.

Adjust length, position, and pinout of your cables or add additional connectors. Get a cable solution designed to make your connections streamlined and secure.

Enhance your user experience with capacitive or resistive touchscreen technology. We’ll adjust the glass thickness or shape of the touch panel so it’s a perfect fit for your design.

We can incorporate HDMI, USB, SPI, VGA and more into your display to achieve your design and application goals.

Easily modify any connectors on your display to meet your application’s requirements. Soldering for pin headers, boxed headers, right angles headers, and any other connectors which your display may require.

Choose from a wide selection of changes including shape, size, pinout, and component layout of your PCB to make it a perfect fit for your application.

Equip your display with a custom cut cover glass to improve durability. Choose from a variety of cover glass thicknesses and get optical bonding to protect against moisture and debris.

Examples might include bezels, gaskets, metal mounting brackets, threaded standoffs or pressure sensitive adhesive (PSA).

Custom backlight configurations can be made with voltage/input current, brightness or colors/NVIS. Perhaps it is just changing the assembly type from array to side LEDs.

Membrane keypad with LED indicators or a rugged mechanical silicone keypad additions. Contact us for any keypad requests.

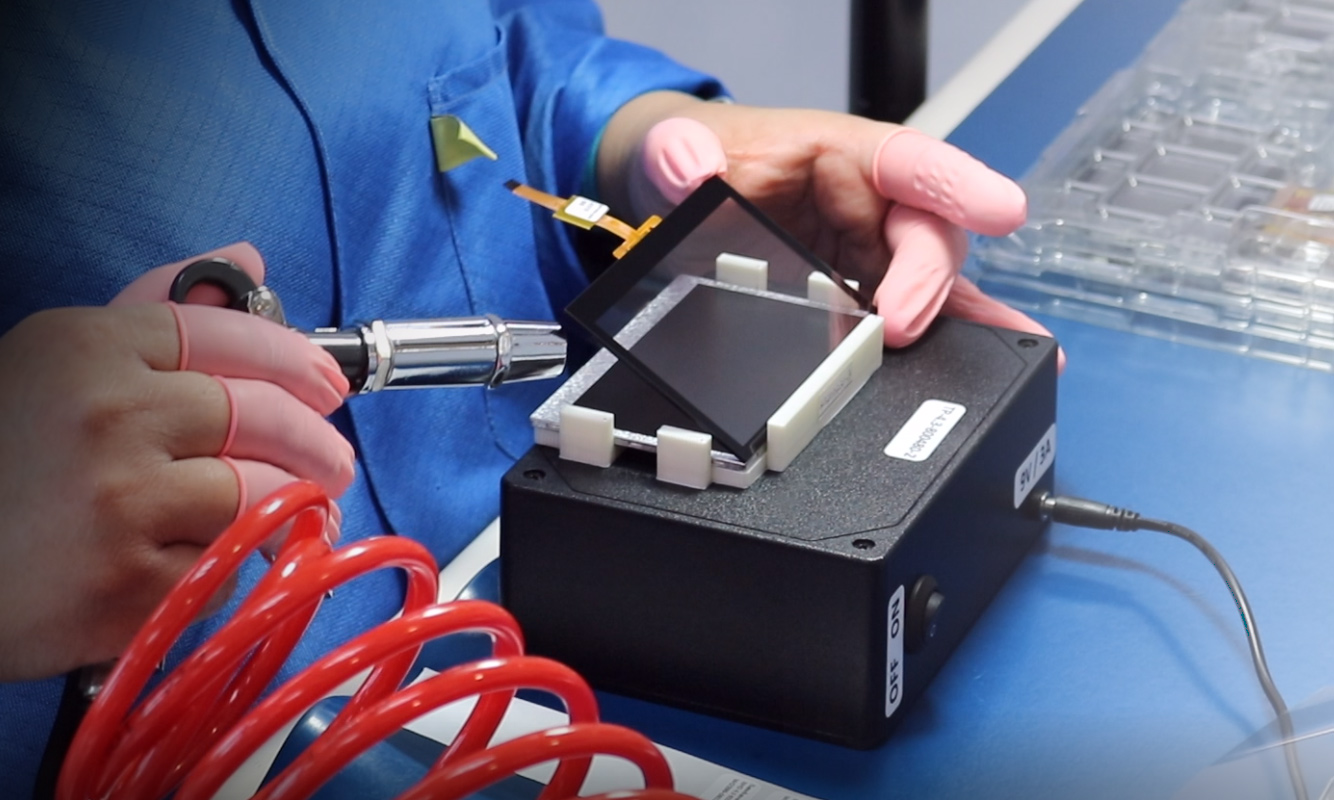

Fully Staffed For In-House Customizations

We have complete control over our display products' design, manufacturing, and quality control processes. Our China based Engineers will work with you on a prototype to validate and test your design.

Interested in a custom display solution?

Get Started